HOTMELT GLUE

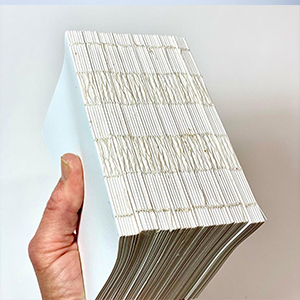

EVA based Hot melt adhesives are solvent-free formulations which become liquid when heated and are applied in molten state. These types of adhesives are a desirable choice for bookbinding application demands due to their ability to meet high line speeds at relatively low cost and minimal waste. Additionally, EVA based hot melt adhesives offer the strength and flexibility as well as other needed qualities for bookbinding’s demanding application requirements. Bound to last from the first page to the very last, we fabricate EVA based hot melts that provide outstanding spine gluing, side gluing, end gluing, casing in and tip-in applications. Our EVA based hot melt bookbinding adhesives give superior page pull strength and assured bonding creating durable book spines. The unique SGAPL bookbinding adhesive is made using high quality raw materials and an advanced production process and offers superior tensile strength for the pages and guaranteed adhesion for all types of paper from newsprint to art paper and coated paper. There are various kinds of bookbinding hot melt adhesive products available for different applications and customized products developed to suit production-line needs.

At SGAPL, we help to improve your end product and streamline your processes with our market proven portfolio of hot melt bookbinding adhesives that focuses on enhancing your quality, increasing efficiency and reducing costs. We provide hot melt glues for two major applications in book binding technique – the spine glue for soft covers and side glue to bond the end sheets of a book or a magazine to the cover. Various factors have to be taken into account. For instance, the paper quality, the glue pot temperature, the dwelling time, feed speed and the application amount.

COMMON USES:

Stitch Books, Textbooks, Magazines, Notebooks, Receipts, Picture Books and for all standard paper qualities in book printing and binding industry.

BENEFITS:

- High flexibility

- Exceptional productivity

- Superior bond

- Excellent heat stability and machining

- Resistance towards charring, gelling and skinning

- Cost effective

- Endurable adhesion

- Odourless to create better working environment

SHIPPING:

HS CODE : 35069999

ORIGIN : HARYANA

LEAD TIME: Generally shipment can be on board within10-15

days. For samples, can be delivered within 7-10 days by air.

PACKAGING AND SHELF LIFE

AVAILABLE IN:25 Kg printed Kraft bags and 0.8-1.2 ton per pallet.

SHELF LIFE:12 months if stored in a cool dry place

HANDLING AND STORAGE

To increase the storage life, this product should be stored at 32°C environment and avoid excessive heat for extended periods of time. It should be kept in a clean, cool and dry environment.

CLEAN UP AND SAFETY INSTRUCTIONS

Consult the equipment manufacturer for cleanup procedures. After clean-up, flush the applicator thoroughly with hot melt to purge the system. To minimize the risk of burns, we recommend the use of eye protection and protective clothing when working near a hot melt applicator. To minimize the risk of flammable vapours, do not exceed a melt temperature above 200°C. Prevent the build-up of vapours. Extinguish all sources of ignition during hot melt use.

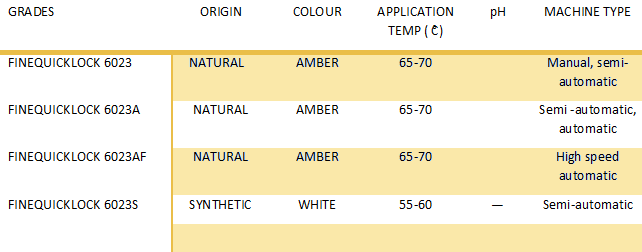

PRODUCT GRADES :

(This is an abbreviated version of the technical data sheet. Please contact us for the complete version.)

Get your order

SUITABLE FOR DIFFERENT TYPES OF MACHINES

Our reference products are appropriate for use with the following machines: Kolbus, Muller-Martini, Rotowinder, Pony, Sulbi etc.

KEY INDUSTRIES

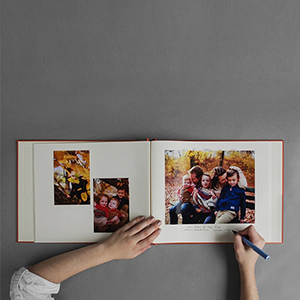

PERFECT BOOK BINDING

Sector

PHOTOBOOK BINDING - ARTPAPER

Sector

DIRECTORY BINDING

related products

COLD BINDING ADHESIVE

?

COLD PASTING ADHESIVE

?

LAMINATION ADHESIVE

?

GELATINE BASED ADHESIVE

?